A Look Inside Liftsafe's Custom Crane Fabrication

At Liftsafe Engineering, we are committed to delivering high-quality crane solutions that meet the rigorous demands of various industries. Our custom crane fabrication process ensures each project is handled with precision and expertise at every stage. Here are the detailed steps involved in the fabrication of our latest 72’-0” crane, from initial planning to final installation.

What to expect from OHSA

While proper material handling keeps supplies moving and workplaces running efficiently, it can also pose serious safety risks. Workers can be struck by, caught between, or crushed by materials, equipment, or vehicles if proper precautions aren't taken. These hazards can lead to severe injuries or even death. The responsibility falls on employers to ensure a safe work environment. By implementing proper material handling protocols, they can protect their workforce and keep the supply chain flowing smoothly.

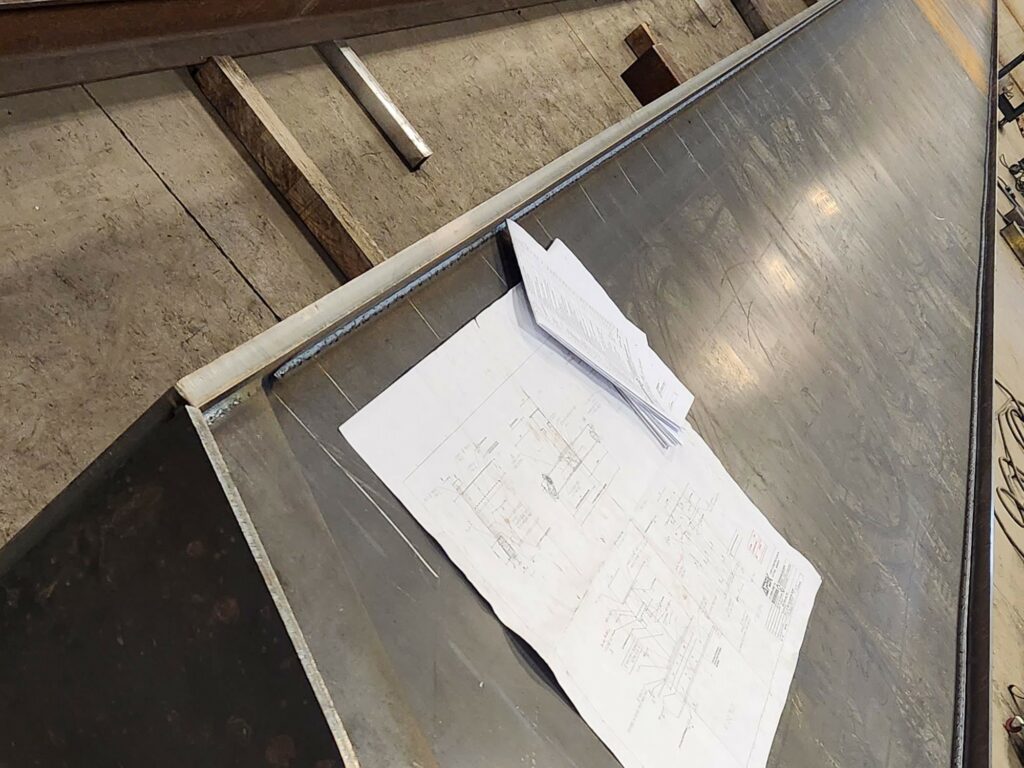

Phase 1: Overhead Bridge Crane Engineering, Planning and Parts Order

The journey begins with planning sessions between our client, sales team, engineering department and shop staff before ordering all essential parts. Our engineering team collaborates with our shop managers to procure high quality materials from trusted suppliers. This initial phase is crucial to ensure the reliability and performance of the final product.

From the cranes that can add capacity to your facility to the ergonomic material handling device that can eliminate work related repetitive strain injuries: Liftsafe brings together our design engineering team and cutting-edge design software to deliver turnkey solutions for our clients in multiple industries. We take a collaborative approach with our clients on each project, as we support them throughout the full project life-cycle, from concept, to detailed design and whole life support.

Phase 2: Start of the Crane Manufacturing Process

With the parts on hand, our skilled team initiates the manufacturing process by setting up the key components of the crane. This involves the precise alignment and assembly of critical structural elements, ensuring a solid foundation for the entire build. During this phase, we focus on performing large fillet welds, which are essential for creating strong and durable connections between the crane’s primary components. The meticulous attention to detail during the setup and welding phase is crucial in laying the groundwork for a reliable and high-performing crane.

Phase 3: Box Girder Welding

Progress continues with the completion of approximately 280 feet of continuous welds on the box girder of the crane. Each weld is expertly executed to ensure the structural integrity and safety of the crane, highlighting the craftsmanship and dedication of our team.

Phase 4: Precision welding of heavy-duty crane system

The welding process on our crane systems is a testament to the skill and expertise of our certified welders. Throughout this phase, our team relies on their extensive experience to achieve the high-quality welds necessary for a heavy-duty crane system. Liftsafe’s welders are qualified by the Canadian Welding Bureau (CWB), ensuring exceptional quality and service.

Liftsafe’s qualified Canadian Welding Bureau (CWB) welders offer exceptional quality and service. Our team of fully equipped welders are mobile and always at the ready, guaranteeing that your equipment is back up and running as quickly as possible.

Phase 5: Assembly of End Trucks and Box Girder

Following the welding phase, our team proceeds to set up the end trucks and position the box girder on them for final welding. This stage involves precise alignment and secure attachment, preparing the crane for the next steps of painting and assembly.

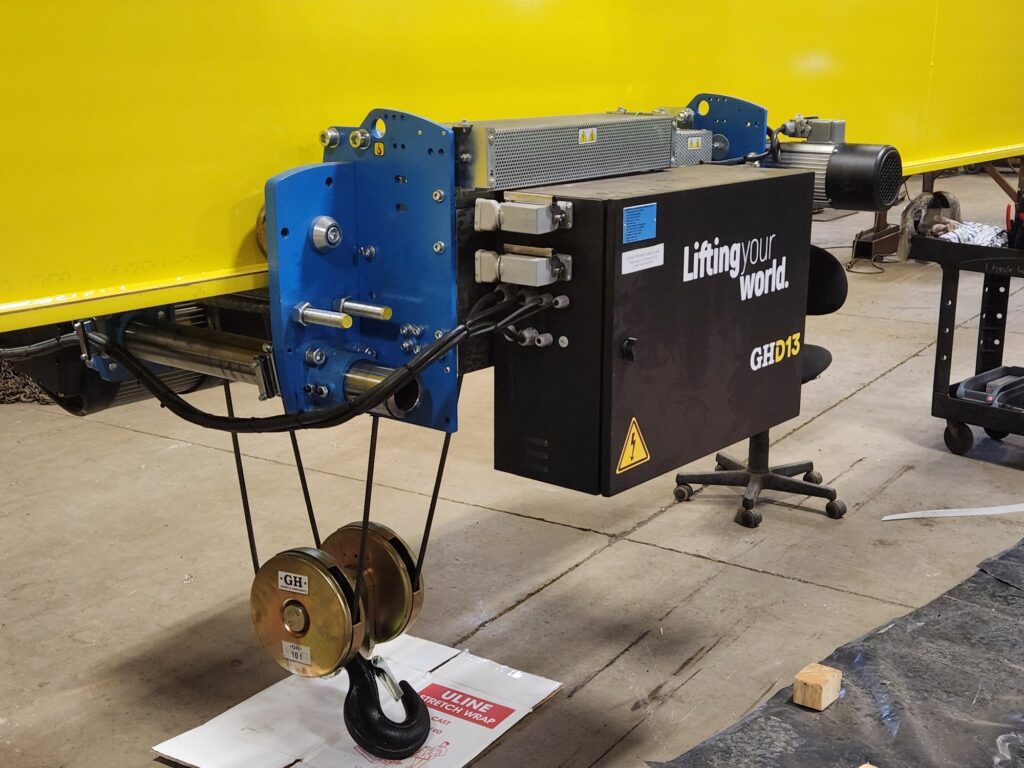

Phase 6: Painting and Mechanical Assembly

As the crane fabrication progresses, we initiate the painting process in our in-house paint shop and begin the electrical and mechanical assembly. This phase involves integrating all components to ensure the crane’s operational efficiency and compliance with safety standards. Our team checks each element to guarantee optimal performance.

Phase 7: Preparation for Delivery

With the painting and assembly complete, the crane undergoes a final test and is prepared for delivery. Our team conducts thorough inspections to ensure every detail meets our stringent quality standards. The crane is then carefully loaded and transported to the client’s site, ready for installation.

Phase 8: Final Overhead Bridge Crane Installation

The culmination of our efforts is the successful installation of the crane at the client’s facility. With over 20 years of experience, the installation process is executed smoothly and efficiently, ensuring that the crane is operational and meets the client’s expectations.

Liftsafe Engineering is a premier North American crane manufacturer with over 25 years of experience. We specialize in manufacturing, installing, inspecting, and repairing industrial cranes, providing both standard and custom solutions tailored to meet our clients’ needs. Our in-house engineering team ensures that every system adheres to rigorous performance and safety practices.

We offer 24/7 crane inspection and maintenance through our online Customer Portal, providing comprehensive support throughout every stage of the crane’s lifecycle. From design and manufacturing to training and aftercare, Liftsafe Engineering is dedicated to delivering exceptional crane solutions.

Our extensive industry knowledge, honed through decades of service, is incorporated into each unique crane product we create. We design and produce major components in-house, allowing us to maintain quality control and provide the proper equipment for every job.

Our 30,000 sq ft fabrication space includes a machine shop, fabrication shop, paint booth, and assembly area, enabling us to bring concepts to reality. Our professional engineers possess expertise in design, safety, manufacturing process optimization, ergonomics, structural analysis, and regulatory compliance.

Liftsafe Engineering is your trusted partner for overhead crane equipment and service. We combine expert service and parts to create reliable, affordable systems. Choose Liftsafe Engineering for all your crane needs and experience the benefits of working with a leader in the industry.

Cam Randell is currently the Vice President of Sales at Liftsafe Engineering. Leveraging over 20 years of experience working with industrial cranes, Cam is an expert in the industry. Prior to joining Liftsafe, he gained extensive experience working with lifting equipment at Bär Cargolift and O’Brien Installations Limited. This deep understanding of the crane industry and its customer needs has made him a valuable member of the Liftsafe Group.