We analyzed our historical school and municipal inspection tenders and these are the top safety inspections that are often overlooked

We recently analyzed our historical tender bids in order to answer the question:

Which inspections are critically important from a safety perspective but often aren’t included in the tendering process?

We looked at school board tenders. We looked at municipal tenders. We even cross referenced our historical winning bids.

With the help of our customer portal database, we uncovered some interesting findings.

This article outlines the top four safety inspections that are often overlooked and why they are important to include in your next inspection tender.

Here is a summary of the top four:

-

Woodshop Inspections

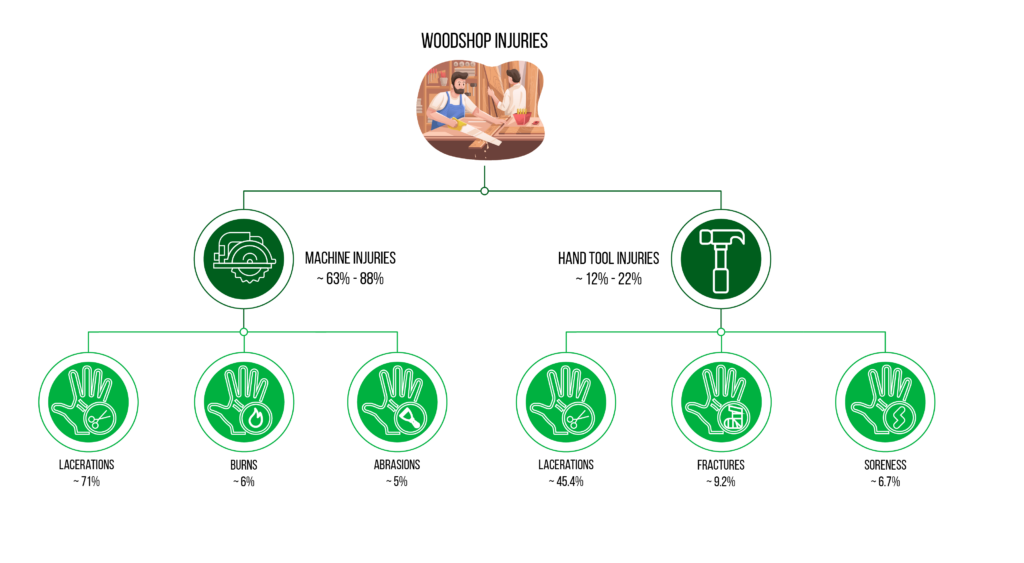

"In Ontario, close to 80% of injuries affecting students using machines in wood shops, automotive shops and similar programs, involve lost or disfigured fingers, hands or thumbs."

- Health and Safety Ontario, 2012.Although the number of injuries that happen in woodshops and other places tend to be low (5% - 7%) compared to overall woodworking injuries, they can be extremely severe when they do.

-

Safe Guarding of Machinery

Machine Guarding is an essential and necessary requirement for schools to ensure students and staff are safe. Lack of Machine Guarding and inadequate lockout procedures are among the top four causes of workplace accidents in Ontario. The number of injuries and their severity continue to be a focus of OHSA, resulting in significant fines and penalties in schools throughout the province by the MOL.

-

Autoshop Inspections

Another area with significant safety risk, annual auto shop inspections are advised to support student and employee’s health and safety. Since failure to ensure your shop safety could result in significant injuries to students, employees, and customers, in addition to potential lawsuits and penalties, it is important that shop supervisors and other stakeholders need to devote time and effort to this critical area.

-

Man Lift Inspections

Usually what is known for Man Lift inspections is that they are required annually. Less known are structural inspections which are required 10 years after the date of manufacture and every 5 years thereafter in accordance with CSA B354.

While these areas and equipment aren’t necessarily in every school or building like a playground or basketball assembly might be, they have the highest potential for serious injuries. The following provides detailed data on what makes these inspections so important.

“It is estimated that 10 to 25 per cent of childhood injuries occur while the child is in school.”

Legal Responsibilities of Supervisory Officers

In Ontario, school boards are required to provide safety to:

- Students, as required by the Education Act (EA);

- Employees, as required by the Occupational Health and Safety Act (OHSA); and

- Anyone after the fact, should a critical injury or death occur on school or municipal property.

Other safety laws that govern school boards and their properties are;

As a general rule, there is a principle known as the Reasonably Prudent Parent Doctrine that says that a school board and its employees or volunteers provide the same standard of care for students as a reasonably careful or prudent parent would.

More detailed information on this can be found in Good Governance: A Guide for Trustees, School Boards, Directors of Education and Communities. Chapter 6 Legal Responsibilities and Liabilities Ontario Public Boards’ Association.

OHSA is more well-known and is outlined in Ontario’s Green Book which is required to be posted in all workplaces. Regulations and guidelines made under OHSA relate to specific standards from a number of certifying or standard setting organizations. These organizations include but aren’t limited to;

- CSA International, also known as the Canadian Safety Association

- First Aid Regulation 1101, under the Workplace Safety and Insurance Act (WSIB)

In reference to any critical injury or death, this falls under the Criminal Code of Canada which assigns criminal liability to organizations. Organizations and the people directing work at them are legally obligated to take reasonable steps to ensure safety of workers and the public.

Under this framework the schoolboard is known as the employer and the Principals or Vice Principals are known as the supervisors.

Woodshop inspections

Surprisingly, there is very little statistical data or study done on school aged children and injuries in relation to woodshops specifically. There have been studies done but none that have been conducted in the last five years.

However, from the statistics that have been gathered, woodshop accidents are a common occurrence in schools. In fact, a study conducted by the National Center for Education Statistics in the United States found that woodshop accidents accounted for approximately 15% of all accidents in schools involving machinery and even more if you take hand tools into account.

The importance of woodshop inspections in schools cannot be overstated. Regular inspections can help identify and address potential hazards before they lead to accidents. In addition, inspections can also ensure that woodshop equipment is properly maintained and functioning properly. This not only helps to prevent accidents, but it also ensures that students are able to learn and work safely in the woodshop environment.

Woodshop inspections need to be performed by trained professionals who are familiar with the specific equipment and machinery used in the woodshop. They should also be familiar with CSA standards, OHSA regulations and other regulations that apply to each specific machine.

During an inspection, the professional should check for potential hazards such as loose or damaged machinery, exposed electrical wiring, and inadequate ventilation. They should also check to ensure that all safety equipment, such as eye and ear protection, is in good working order and readily available to students.

In addition to identifying potential hazards, woodshop inspections should also include a review of the woodshop’s safety policies and procedures. This ensures that students and teachers are aware of the proper safety protocols and are able to follow them.

Key Takeaway:

Regular woodshop inspections are crucial for the safety of students and teachers in schools. They help to identify and address potential hazards before they lead to accidents, and ensure that students are able to learn and work safely in the woodshop environment. By conducting regular inspections, schools can help prevent accidents and ensure that their woodshop classes are a safe and productive learning experience for all students.

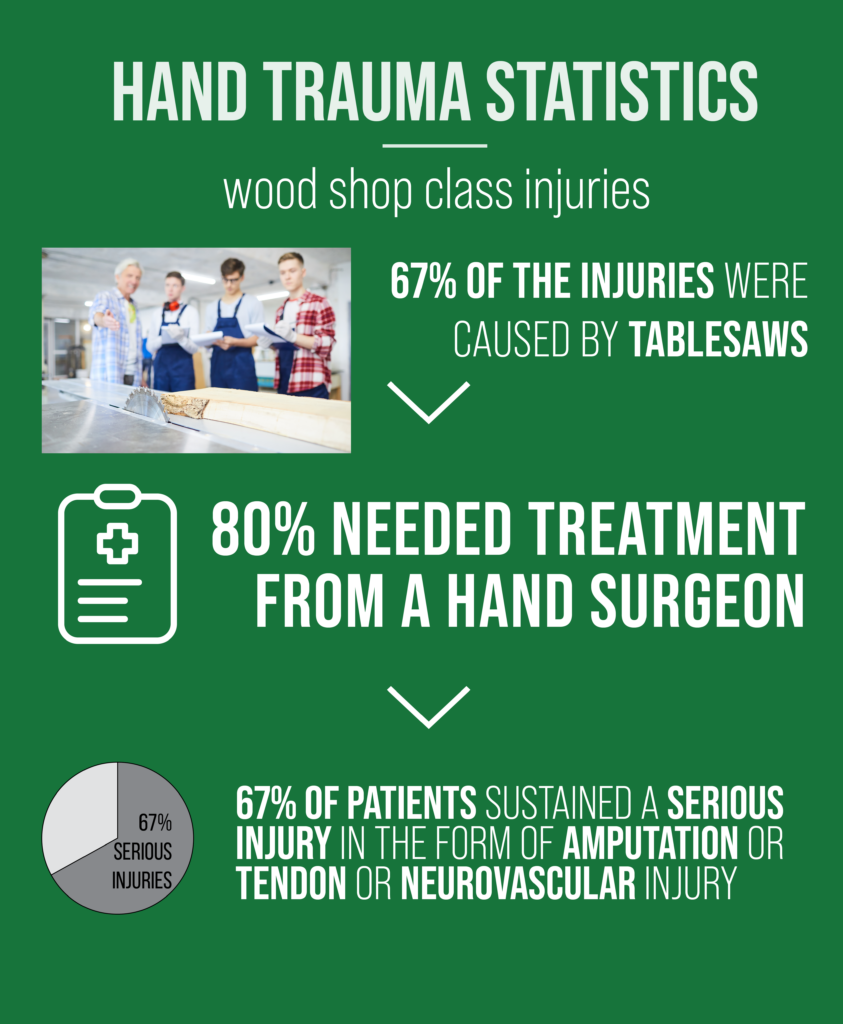

Safe Guarding of Machinery

Overall injuries as a result of working on a tablesaw (cumulative studies from 1987 – 2012)

| Total (%) | Minors (%) | Adults (%) | |

|---|---|---|---|

| Finger/Thumb Injuries | 100 | 3.1 | 96.9 |

| Laceration | 63.8 | 65.1 | 63.9 |

| Fracture/Dislocation | 12.6 | 14.6 | 12.6 |

| Amputation | 13.9 | 12.4 | 14.2 |

| Other | 9.7 | 11.5 | 9.6 |

Machine guarding is a crucial aspect of safety in any workplace or classroom that uses machinery. According to statistics from the Occupational Safety and Health Administration (OSHA), machinery-related accidents account for approximately 12% of all workplace fatalities.

Keep in mind that these statistics are based on experienced operators in a workplace as opposed to students in school. This highlights the importance of implementing effective machine guarding measures in order to prevent accidents and keep workers safe.

One of the key benefits of machine guarding is that it helps to prevent workers from coming into contact with moving parts of machinery.

This is particularly important for machines with high speed or heavy-duty operations, as these can cause serious injuries if workers are not properly protected. By using guards such as barriers, guards, and emergency stops, workers can be kept at a safe distance from the machinery and prevent accidents from occurring.

Another important benefit of machine guarding is that it helps to improve the overall safety of the workplace or classroom. By reducing the risk of accidents, machine guarding can help to create a safer and more productive learning environment for students. This can lead to improved educational outcomes, as students will feel more secure and confident in their ability to learn how to use equipment safely.

In addition to preventing accidents and improving the safety of the classroom, machine guarding can also help to reduce the cost of injuries. When accidents do occur, they can result in significant financial losses for the students, teachers and the school. This includes costs associated with medical treatment, lost wages, and potential legal action. By implementing effective machine guarding measures, schools can significantly reduce the likelihood of accidents occurring and the associated costs.

Key Takeaway:

Overall, the statistics demonstrate the importance of machine guarding in schools. By preventing accidents, improving safety, and reducing costs, machine guarding is an essential element of any successful workshop safety program.

Auto Shop Inspections

Auto shop inspections are also an important part of ensuring the safety of students and teachers in schools. Statistics show that auto shop accidents are a common occurrence in schools, with a study conducted by the National Center for Education Statistics finding that auto shop accidents accounted for approximately 14% of all accidents in schools involving machinery.

Regular inspections can help to identify and address potential hazards in auto shop classrooms, ensuring that students and teachers are able to work and learn safely. During an inspection, trained professionals check for potential hazards. They also ensure that all safety equipment, such as gloves and ear protection, is in good working order and readily available to students.

In addition to identifying hazards, auto shop inspections should also include a review of the auto shop’s safety policies and procedures. This ensures that students and teachers are aware of the proper safety protocols and are able to follow them.

Regular auto shop inspections are crucial for the safety of students and teachers in schools. They help to identify and address potential hazards before they lead to accidents, and ensure that students are able to learn and work safely in the auto shop environment. By conducting regular inspections, schools can help prevent accidents and ensure that their auto shop classes are a safe and productive learning experience for all students.

In terms of the frequency of auto shop inspections, it is recommended that they be performed at least annually. This ensures that any potential hazards are identified and addressed on a regular basis, and that the auto shop environment remains safe for students and teachers.

Conducting regular auto shop inspections in schools continues to be an important health and safety issue.

Key Takeaway:

Classroom safety is a priority, but it can sometimes be a challenge to incorporate into Auto Shops depending on class sizes. Injuries in auto shops continue to be at the forefront of school related injuries and often result in the more severe and life-threatening injuries.

A recent focus of a MOL Blitz concluded that the top three areas of concern within these departments are: Inadequate Guarding/Shielding, Missing Inspections, and Fall Protection Hazards.

Man Lift Inspections

Man lift inspections are an important part of ensuring the safety of workers and the public in Canada. According to statistics from the Canadian Centre for Occupational Health and Safety (CCOHS), accidents involving man lifts result in approximately 70 deaths and 400 serious injuries each year in Canada.

In order to prevent these accidents, it is crucial that man lifts are regularly inspected to ensure that they are in good working order. In Canada, man lift inspections are regulated by the Occupational Health and Safety Act (OHSA) and its associated regulations.

Under the OHSA, employers are required to ensure that man lifts are inspected by a competent person on a regular basis. This person must be qualified and trained to identify potential hazards and ensure that the man lift is operating safely. The frequency of inspections will vary depending on the type of man lift and the conditions in which it is being used, but they should be performed at least once every 12 months.

During these inspections, the competent person must check for potential hazards such as loose or damaged components, inadequate lighting, and exposed electrical wiring. They must also ensure that all safety equipment, such as fall protection devices and emergency stop buttons, is in good working order and readily available to workers.

Also, according to CSA B354, structural inspections of all man lifts must be performed under the direction of a professional engineer if any of the following circumstances apply as of 2003;

- 10 years after the date of manufacture and every five years thereafter.

- After an incident that could affect the structural integrity or stability of the aerial such as collision, overloading, fall arrest, electrical contact, shock loads or loss of stability.

- After a change of ownership, unless a complete history of maintenance and inspection records are included with the unit.

Required qualifications for personnel providing these inspections are CSA standard W178.2 for weld inspections and CGSB standard 48-9712 for non-destructive testing.

In addition to conducting regular inspections, employers are also required under the OHSA to keep records of all man lift inspections and any repairs or maintenance that are performed. These records must be kept for at least two years and must be made available to workers, the Ministry of Labour, and any other interested parties.

Key Takeaway:

There are a number of different factors and types of inspections that are required when you have a man lift. It is important that good records are kept and that your staff are either well informed on each inspection and when it is needed or that this is outsourced to a third party that can ensure all inspections are complete according to regulations.

Conclusion

The main conclusion from this text is that there are several safety inspections that are often overlooked in the tendering process, but are critical from a safety perspective. These inspections include wood shop inspections, safe guarding of machinery, auto shop inspections, and man lift inspections. These inspections are important because they can help prevent accidents and injuries in schools and municipalities, and ensure that students, employees, and the public are protected from potential hazards. It is recommended that these inspections be included in the tendering process in order to ensure the safety of all stakeholders.

Now we would like to hear your thoughts:

What’s your #1 takeaway lesson from this analysis?

Or maybe you have a question about the findings.

Either way, reach out to PARCS if you have any questions.