Related to: How to Justify Ergonomic Improvements, Benefits of Ergonomic Solutions, Work-Related Musculoskeletal Disorders and Ergonomic Solutions

The retention of human resources is a key factor in the competitiveness of Canadian companies. Therefore, it is relevant to identify and address one of the major barriers to productivity, Musculoskeletal Injuries (MSIs). These sprains, strains and overuse injuries affect the joints, muscles and nerves and often result in consequences ranging from reduced productivity to significant time loss or long-term disability with its associated costs.

In the Canadian workforce alone it is estimated that time loss occupational injuries arising from MSI’s resulted in a direct cost of 3.2 billion dollars to the Canadian economy in 1998. Creating a safe, productive and positive workplace is critical to the success of all stakeholders in any given industry. Ergonomics seek to eliminate risk factors that lead to musculoskeletal disorders and other types of injury. Ergonomics training can empower companies and individual workers to identify potential sources of injury, prevent potential hazards, and optimize working conditions.

In Canada, each province has its own occupational health and safety legislation and the Canada Labour Code governs organizations under federal jurisdiction. Specific acts and regulations can vary but the general principles will always remain the same: employers are responsible for maintaining the health and safety of employees at their work sites. Each employee also has the responsibility to work safely and protect the safety of themselves, their co-workers and the general public where applicable. When employees are taught to recognize risk factors that may cause injury it leads to a safer and more productive work environment.

Ergonomic program elements include things such as stretch programs, ergonomic workstation design, formal job rotation, job matching, and documented ergonomic risk identifications. A successfully implemented ergonomic program helps to:

- Reduce the incidence and severity of musculoskeletal injuries.

- Keep skilled and valuable people at work.

- Reduce absenteeism.

- Achieve greater production consistency.

- Achieve higher levels of quality management.

- Improve operating profits by lowering injury costs and improving production levels.

The National Seafood Sector Council conducted a survey of ergonomics within the workplace. The purpose of the survey was to implement strategies to meet the long-term human resource needs of the Canadian seafood processing industry as well as review current practices and demand for training in new employee development and skills training, employee refresher training, occupational health and safety training, and specific ergonomics training.

Some noteworthy findings from this survey include:

- Only 26 percent of respondent companies currently provide ergonomic prevention training to the general production and maintenance workforce.

- The majority of respondents indicated they use a joint health and safety committee but 50% of the health and safety committees surveyed never conduct ergonomic training.

- 66 percent of respondents have monthly meetings regarding health and safety issues.

- New hires make up almost 25 percent of the respondent’s total workforce. This high percentage indicates the necessity of ensuring effective, targeted education for individuals at the orientation/training stage.

- Throughout Canada, almost 110,000 young people were seriously injured on the job in one year alone. These statistics mean injured young people represent one in every four injured workers.

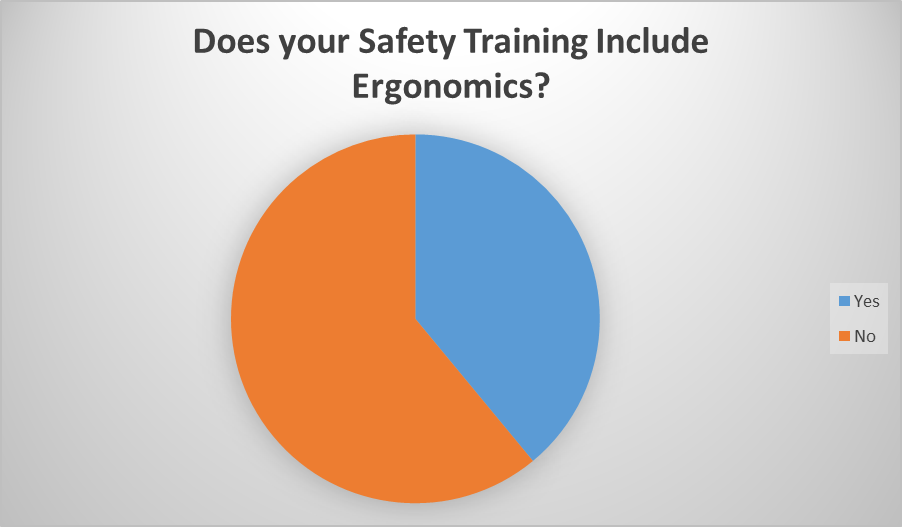

- In regards to safety training, 52 percent of companies have a verbal orientation but only 39% of respondent’s safety training includes ergonomics. This makes it one of the most common challenges associated with the administration of Occupational Health and Safety Programs.

- When asked directly about the level of ergonomic education, 89 percent of respondents had not received in-depth training in this area.

- 38 percent of respondents had specific strategies to deal with MSI’s, meaning that 62 percent do not.

- 46 percent of respondents said that workers are never consulted regarding changes in tools, equipment and processes.

Based on the results of this survey there is a demonstrated need for ergonomic training within the seafood-processing sector. The benefits of ergonomic training in any industry are endless. These benefits include: reducing costs, improving productivity, improving quality, improving employee engagement and creating a better safety culture. More industries need to be studied to see if there is a common theme of the need to be more educated on the topic of ergonomics!

What are some of the benefits you’ve seen at your facility?

Do you plan on spending increased time, attention and resources on ergonomics this year?

How do you make the case for your ergonomic processes?

Do you believe that there will be a common theme across industries if a similar study was conducted?

Data Source: http://www.mun.ca/shellfishohs/WorkRelMuscDis/Ergonomicsintheworkplace.pdf