Related: Below the Hook Attachment Inspections

What are Below-The-Hook Attachments?

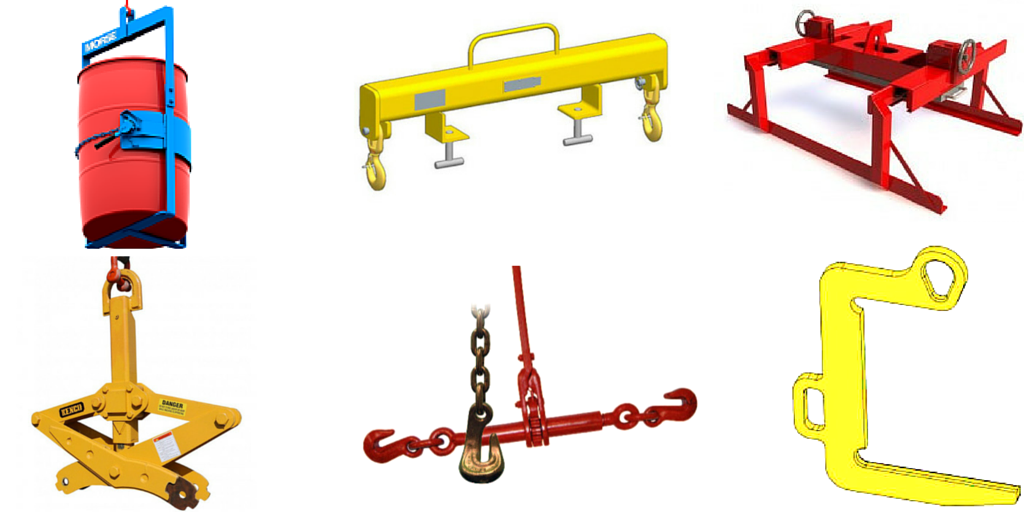

These diverse lifting devices come in a variety of different styles including c-hooks, coil grabs, and coil lifters, and they can be attached to a variety of lifting equipment like cranes, spreader beams, book blocks, sheet lifters and roll handling equipment.

Like I stated before Bellow-the-Hook lifting devices have a wide variety of diverse styles which is why they are broken down into four very distinct categories:

-

Structural and Mechanical Lifting Devices:

These are often unique designs and often include one of the following mechanisms: load-supporting lifting devices, friction type pressure gripping lifting devices, indentation type gripping lifting devices or cask lifting fixtures.

Inspections:

Initial Inspection: This should be completed before any use by a qualified inspector, and should be completed for all new, modified or repaired lifting devices. This will help to ensure the device is safe to use.

Frequent Inspection: The operator of the bellow the hook attachment will visually inspect the lifting device at the beginning of each shift OR before each use. They will also keep a record of the following:

- Any structural deformation, cracks or excessive wear

- Any loose or missing fasteners, covers, stops, nameplates or guards

- They will make sure all operating mechanisms and automatic hold and release mechanisms have no maladjustments that are interfering with the operation of the machine.

Periodic Inspection: Lifting devices and how you use them can be broken down into three distinct categories, and based on the category that they fall under determines if they require annual, semi-annual or quarterly inspections.

- Normal: the machine is operated with various weights that are within the rated load limited, or has uniform loads that are less than 65% of the rated load. If it falls under this category the machine requires annual inspections.

- Heavy: the machine is operated within the rated load limit, but it exceeds normal service. These machines should be inspected semi-annually.

- Severe: these machines are operated at normal or heavy service levels and operate under abnormal operating conditions, which is why these machines need to be inspected quarterly.

These inspections should include checking over the following: the bolts and fasteners, looking for any malfunctioning parts, checking for any cracked/worn gears, pulleys, sheaves, sprockets, bearings, chains and belts and finally looking for excessive wear of friction pads, linkages, hoist attaching points, load support shackles, pins, and any other mechanical parts

Maintenance:

A preventive maintenance program should be established based on what the inspections tell you about the machine and your manufacturers recommend the user guide.

Operation:

A Quick 12 Step Check List

- Make sure the loads’ weight is correctly distributed before the lifting device is put to use.

- Before you lift an item ensure the below-the-hook-attachment is not kinked or interwoven.

- Apply the lifting device to the load following any established procedures.

- Unless for test loads do not load the lifting device over its rated capacity

- Ensure you test the lifting devices controls before each shift, and adjust any if necessary.

- Place the attached load on the floor/ground and after using the device properly store away the lifting device.

- Observe the condition of the below-the-hook-attachment and the lifting device, and ensure that there are no defects that will affect the continued safe use and operation of the lifting device.

- Do not use the lifting device for side pulls or sliding the load.

- Do not use a lifting device that has any sign that indicates that it is not functioning correctly or not in service

- Do not remove any sign that indicates the machine is not in working order unless you have explicated approval from the person who put it there.

- Make sure you store the lifting device in a dry location

- Make sure that no marking or tags are not removed or defaced and if they ensure they are replaced.

-

Vacuum Lifting Devices

Inspections:

Initial Inspection: Before using a qualified inspector should inspect all new or repaired vacuum-lifting devices to ensure they are safe to use.

Frequent Inspection: The designated person or operator shall inspect the vacuum lifting attachment before each use/shift. They shall record any of the following if they notice them:

- Any deformations, cracks or excessive wear on the load-bearing parts

- Ensure that the vacuum generator is giving adequate output

- Check for any cuts, tears, excessive wear or foreign particles in/on the vacuum pad seal rings.

- Look for any leakage, cuts, kinks or collapsed areas of the vacuum lines and/or connections.

- Look for any leaks or damage to the vacuum reservoir.

- Testing the vacuum system to ensure it is if functioning properly by attaching a non-porous, clean test plate to the vacuum pads then stopping the vacuum. The vacuum levels in the system should not decrease by more than the rate, which is sated by the manufacturer.

Periodic Inspections: These should be completed on an annual, semi-annual or quarterly cycle depending on how you use your bellow the hook attachment the different types of usages can be broken down into three categories.

- Normal: the machine is operated with various weights that are within the rated load limited, or has uniform loads that are less than 65% of the rated load. If it falls under this category the machine requires annual inspections.

- Heavy: the machine is operated within the rated load limit, but it exceeds normal service. These machines should be inspected semi-annually.

- Severe: these machines are operated at normal or heavy service levels and operate under abnormal operating conditions, which is why these machines need to be inspected quarterly.

These inspections should include looking for the following: any evidence of looseness, wear, cracking, corrosion or deformation. The inspector shall check for any external evidence of damage to the supporting structure, motors, controls or any other auxiliary components. They will also look for any missing warning labels and replace any that are missing.

Maintenance:

One should create a preventive maintenance program based on the recommendations made by the manufacturer of the bellow the hook attachments. You should ensure that any replacement parts are equivalent to the original specifications, and you must make sure the generator, pads, sealing rings, mufflers and filters are maintained and cleaned in accordance with your manufacturers’ specifications.

Operation Tips

- Before you start the lift, ensure the “vacuum on” indicator has reached the required level. At this time also make sure the vacuum lifting device has been correctly applied and a stable vacuum level exists, this can be tested by lifting the load several inches and observing the conditions of the load and vacuum

- Look at the condition of the lifting device before you use it and during the duration of the operation. If you notice a defect that is affecting the continued safe use of the lifting device you should remove it from service.

- Place any attached loads on the floor/ground and after each use makes sure you properly store your lifting device.

- Before it is used on a lift test check the controls of the bellow the hook attachment, and if needed adjust/repair them before operations begin.

- Do not load the lifting device if the load is over its rated capacity or it is a load it is not designed for.

- Ensure you apply the lifting device to the load following the pre-established procedures.

- Before you lift to make sure the lifting device ropes/chains are not kinked or interwoven.

- Make sure the load is correctly distributed before lifting.

- Do not use the lifting device for any side pulls or sliding the load.

- Warn everyone in the vicinity of the lifting device and place the load on the floor/ground if it is possible if the power goes off when the load is being lifted.

- Make sure you do not use the device if it has a sign stating that it is out of service, and do not remove any of these signs without the explicate approval of the person who places it there.

- Ensure you store the lifting device in a dry secure place when not in use.

- Make sure that all markings/tags are in place and replace any that are missing or defaced.

-

Close Proximity Operated Magnets

These devices are meant for single or multiple steel piece handling operations.

Initial Inspection: This inspection should be completed by a qualified inspector and they inspect any new, modified or repaired lifting magnets to ensure they are safe to use.

Frequent Inspection: the operator or a designated person at the beginning of each shift or before use should complete this. They should check the following:

Frequent Inspection: this should be completed by the operator or a designated person at the beginning of each shift or before use. They should check the following:

- That the lifting magnet face is free from any foreign materials and that the magnet is smooth.

- They should check the lifting bail or sling suspension to ensure it is in the proper condition

- They should ensure the control handle is in the proper condition and operation.

- They also should make sure the current indicator (if applicable) is in the proper condition and operation

- They will ensure the labels, markings and indicators/meters are legible.

- They will also make sure the electrical conductors are free from loose connections, corrosion or damage to insulation.

- Finally, they will make sure the battery is correct for the electrolyte level and make sure there is no corrosion in the battery posts or connectors.

Periodic Inspections: These should be completed on an annual, semi-annual or quarterly cycle depending on how you use your magnetic bellow the hook attachment the different types of usages can be broken down into three categories.

- Normal: the machine is operated with various weights that are within the rated load limited, or has uniform loads that are less than 65% of the rated load. If it falls under this category the machine requires annual inspections.

- Heavy: the machine is operated within the rated load limit, but it exceeds normal service. These machines should be inspected semi-annually.

- Severe: these machines are operated at normal or heavy service levels and operate under abnormal operating conditions, which is why these machines need to be inspected quarterly.

These inspections should include checking for the following: any evidence of deformation, wear, corrosion and will check to ensure all of the members, fasteners, locks, switches and warning labels are in place. The inspector will check the operation and condition of the electrical components of the magnetic below the hook attachments. Finally, the magnet coil test will be completed to check for ohmic/ground readings and any readings will be compared to the manufacturer’s standards.

Maintenance:

A preventive maintenance program should be established based on recommendations made by the manufacturer and should take into consideration the results of the inspections. Before any adjustments and repairs begin on a lifting magnet or its controls maintenance personnel should take the following precautions: Ensure that all sources of the power of the magnets are disconnected, locked out, tagged out or flagged and make sure the magnet that is removed for repairs is tagged as defective.

Operating Tips of Magnetic Below the Hook Attachments:

- Ensure the load is placed on the floor and after it is used make sure the device is properly stored before leaving.

- Before using a bellow the hook attachment ensures you test all of the controls and if necessary complete any adjustments or repairs.

- Do not load the lifting device if it is larger than its rated capacity

- Make sure you apply the lifting device to the load following the pre-established procedures.

- Before you lift to make sure the lifting-device ropes/chains are not kinked or interwoven

- Make sure the load is correctly distributed before lifting

- Ensure the temperature of the load does not exceed the maximum allowable limits

- Do not use the lifting device to slide or pull anything

- Make sure you keep the lifting magnet face and magnet contact area clean

- Keep an eye on all meters and indicators of the lifting magnet and ensure they conform to lifting equipment rated capacity

- Make sure the load is within the magnet’s rated capacity or application capacity

- Before you start to lift, lift the load several inches to ensure the load is securely attached to the magnet

- Do not use or remove any signs/machines that have a sign stating that the machine is dangerous or out of use.

- Make sure you store the lifting device in a dry safe location when not in use.

-

Remote Operated Magnets

Inspections:

Initial Inspection: This inspection should be completed by a qualified inspector and they inspect any new, modified or repaired lifting magnets to ensure they are safe to use.

Initial Inspection: This inspection should be completed by a qualified inspector and they inspect any new, modified or repaired lifting magnets to ensure they are safe to use.

Frequent Inspection: Either the operator or designated personnel will visually inspect the magnetic lifting device at the start of each shift or before use. They will look/check the following:

- They will ensure the magnet is smooth and look for any presence of foreign materials.

- They shall check the magnet’s suspension system

- Finally, they will look at all visible electrical conductors that do not require disassembly to view

Periodic Inspections: These should be completed on an annual, semi-annual or quarterly cycle depending on how you use your magnetic bellow the hook attachment; the different types of usages can be broken down into three categories.

- Normal: the machine is operated with various weights that are within the rated load limited, or has uniform loads that are less than 65% of the rated load. If it falls under this category the machine requires annual inspections.

- Heavy: the machine is operated within the rated load limit, but it exceeds normal service. These machines should be inspected semi-annually.

- Severe: these machines are operated at normal or heavy service levels and operate under abnormal operating conditions, which is why these machines need to be inspected quarterly.

These inspections shall check for the following: deformation, wear, and corrosion of any member, fasteners and lifting parts. The inspector will check to ensure the proper operation on the condition of the electrical components and finally, they will complete a magnetic coil test for ohmic/ground readings and compare these results to the manufacturer’s standards.

Maintenance:

Following the recommendations made by the manufacturer, you should create a preventive maintenance program. Before any adjustments/repairs are made keep this in mind: make sure all sources of magnet power are disconnected, locked out, tagged out or flagged, and make sure the magnet is removed for repairs and labelled as defective.

Daily Operation Tips and Tricks to Keep in Mind:

- Ensure to place any attached loads on the floor/ground and after use, make sure you properly sore the device before leaving.

- Ensure you test all of the control before using it, and do not operate until they are properly adjusted or repaired if required.

- Make sure you do not load the lifting device higher than its rated capacity

- Ensure you apply the lifting device to the load as recommended by the established procedures

- Before you lift make sure the ropes/chains are not kinked and that the lines are not interwoven.

- Make sure the load is correctly distributed before using the lifting device

- Make sure the temperature of the load does not exceed the limits

- Do not use the lifting device for side pulls or sliding the load

- Make sure you do not use the lifting magnet if it is tagged with a do not operate sign or anything similar; do not remove any signs that state this unless you are told by an authorized person to do so.

- Make sure you store the lifting device in its designated location when it is not in use

Below the hook attachments are extremely diverse and can be used in a lot of different applications, which is why it is so important to ensure they are inspected regularly. Regular inspections and maintenance will ensure that these heavy, duty machines last for a long time and are always ready to work when you are.

Do you use a bellow the hook attachments?

How has your bellow the hook attachments benefited you?

What topic would you like to see in the next posting?

Comment below to share your thoughts!

For more information feel free to read this article.